Drying

- Home

- Technology Examples

- Drying

Gyrotron Beam Drying

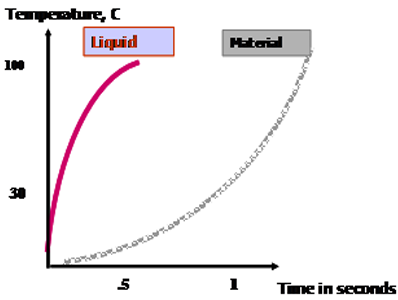

Because of its high power density and frequency, the Gyrotron Beam can heat materials with different heating rates– depending on material absorption properties. In particular, liquids and especially water have higher absorption than most materials that are wetted.

In many cases the Gyrotron Beam can be a cost effective alternative for drying organic and non-organic materials, polymer resins, ceramics, paints, etc. Benefits include reduced space requirement, lower operating costs and enhanced production.

In addition to the Beam’s ability to ultra rapidly and exclusively heat water and other liquid solvents, it allows the incorporation of the process directly into the production line, reducing space requirements and wetness (even to 0% ). Examples include, drying fiberglass, drying pulp and paper, paints, enamels coatings, etc. The Gyrotron Beam can also be used for drying materials that are sensitive to heat. All of these tasks cannot be accomplished as efficiently or effectively by using conventional heat sources such as hot air, gas and infrared.

Drying Porous Materials

Drying porous materials by conventional heating sources takes significant time and energy. The main problem is that moisture heats directly by infrared or hot air only on the surface of the drying object. Deeper inside the material the Beam heats through thermal conductivity that is extremely low for porous materials. Drying moisture from the depth, for example, of only 10 mm requires 10 times longer heating time. In other words, it requires 10 times longer drying in furnace and significantly more energy.

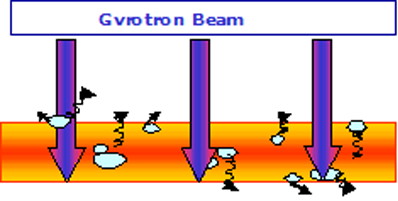

The Gyrotron Beam is the perfect heating source because it penetrates inside of material; heats primarily with a fast evaporation time. Moreover, the Gyrotron Beam power density can be programmed to correspond to the degree of wetness, protecting product integrity while supporting very high production speeds.

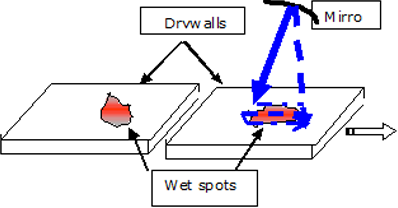

Wet spots in drywall, papers and similar products can be exclusively dried before storing while they are on production conveyor.

Drying Polymers

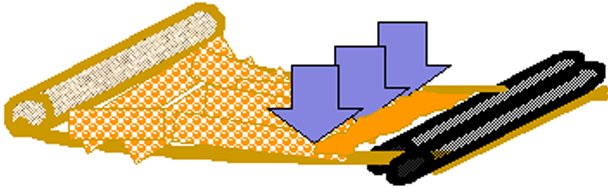

The Gyrotron Beam exclusively heats and pre-cures resin- water-soaked fiberglass, increasing production rate significantly over conventional methods.

Drying Organic Solvents

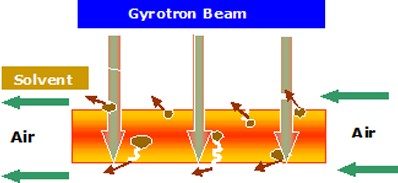

Water drying takes a lot of energy because of its high enthalpy of evaporation. Organic solvents require significantly less energy but create dangerous explosive gases during evaporation. Gyrotron Beam provides safe drying because the explosive gas dissolves and is removed by flow of air that is transparent to the Beam. This reduces energy consumption and drying time.