Beam Plastics/Adhesive/Composite Processing

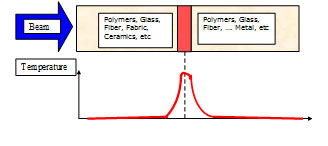

Gyrotron Beam Polymer Curing

The Gyrotron Beam’s is able to selectively heat the catalyst to a high temperature, much higher than the polymer, ensuring short curing time. A curing time of seconds can be achieved for many kinds and thicknesses of polymers.

All types of heat treatment processes for plastics, composites, prepregs, adhesives and other polymer-based materials benefit from using the Gyrotron Beam, which enhances process speeds and product integrity, eliminates the need for massive heaters (furnaces, dies, etc.), reduces production costs, extends shelf and pot life, and increases product quality. In addition, large size and complex-shaped parts are ideal candidates for gyrotron processes.

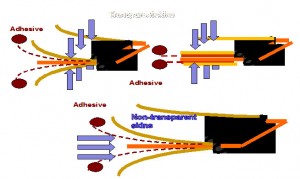

Concept of Adhesives Processing

The Gyrotron Beam can be focused and directed allowing rapid and selective processing of adhesives and resins, with controllable heating of parts being joined. This opens innovative opportunities such as using high-temperature adhesives for joining materials with low melting points (due to ultra-rapid heating that is faster than thermal conductivity). Often, this eliminates the need for cleaning/pre-treating of bonding surfaces, increases adhesion and production rates, saves energy and production space, lowers labor costs by reducing the number of assemblers and operators, and improves plant environment by reducing heat, emissions, and dust, etc.

Example of using the Gyrotron Beam in continues manufacturing of construction panel. Wide (up to 10’) composite panels can be produced with production speed of 10’ (3 m) per min and more.

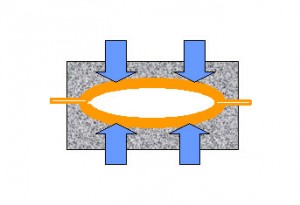

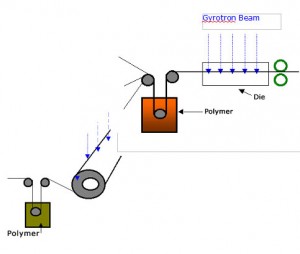

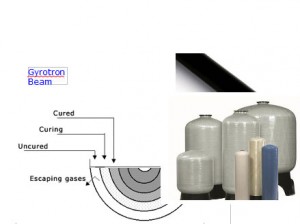

Gyrotron Beam Pultrusion

Gyrotron Beam Pultrusion

Volumetric ultra-rapid heating and curing of resin-soaked materials by the Gyrotron Beam gives the opportunity to significantly reduce die lengths (to a few inches) and increase processing rates as well as part widths by many times.

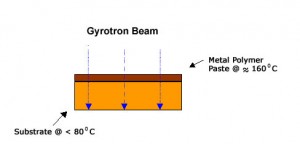

Gyrotron Beam Polymer Coating

The Gyrotron Beam can cure polymer based pastes, lacquers, paints, etc. rapidly (hundreds of sq. feet per minute). This includes using low-temperature substrates as well as process multi-layer systems, and heating each layer and substrate to different temperatures. This opens new opportunities in anti-corrosion coatings, metalizing, etc.

Gyrotron Beam Polymer Molding

Polymers can be processed through the mold made from a transparent for the Gyrotron Beam material such as quartz, Teflon, ceramics, etc.